In the realm of construction engineering, the management of thermal expansion in concrete structures remains a critical yet often overlooked aspect of design integrity. As temperatures fluctuate, concrete expands and contracts, generating internal stresses that can lead to cracking, structural deformation, or even failure if not properly addressed. The science behind compensating for these dimensional changes revolves around the strategic implementation of expansion joints and the materials that facilitate their function. This field, often referred to as expansion joint material science, combines principles of physics, material engineering, and practical construction methodologies to ensure longevity and safety in infrastructure.

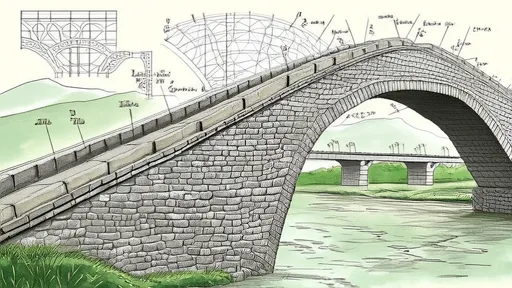

Concrete, like most materials, exhibits a measurable response to thermal variation. Its coefficient of thermal expansion, typically ranging between 8 to 12 micrometers per meter per degree Celsius, might seem negligible at first glance. However, when considering the scale of modern structures—bridges spanning hundreds of meters or high-rise buildings subjected to seasonal temperature swings—the cumulative movement can reach several centimeters. This movement isn't merely horizontal; differential heating can create complex three-dimensional stress patterns that challenge conventional structural designs. Without adequate compensation, these forces can cause spalling at edges, misalignment of structural elements, or water infiltration that accelerates corrosion of reinforcing steel.

The historical evolution of expansion joint systems reveals a fascinating trajectory of innovation. Early engineers used simple gaps filled with bituminous materials or oakum, which provided basic separation but limited movement capacity and durability. The mid-twentieth century saw the introduction of synthetic rubber and neoprene-based systems, offering improved flexibility and weather resistance. Today's materials represent a sophisticated fusion of polymers, metals, and composites engineered for specific performance characteristics. These advancements didn't emerge from theoretical research alone but were driven by dramatic structural failures that underscored the consequences of inadequate expansion accommodation.

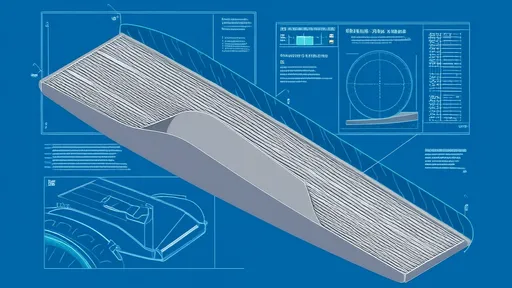

Modern expansion joint materials must fulfill multiple demanding criteria simultaneously. They require sufficient flexibility to accommodate expected movement ranges, which can vary from ±25% in building joints to ±50% in bridge applications. Compression set resistance ensures the material returns to its original shape after repeated cycling, while tear strength prevents damage during installation and service. Environmental factors demand resistance to ozone, ultraviolet radiation, and temperature extremes from -40°C to 80°C. In specialized applications, additional properties like fire resistance, chemical compatibility with deicing salts, or acoustic insulation become critical design parameters.

The chemistry behind these advanced materials involves sophisticated polymer formulations. Thermoplastic elastomers like TPU (thermoplastic polyurethane) offer excellent abrasion resistance and mechanical properties, while thermoset rubbers like EPDM (ethylene propylene diene monomer) provide superior weather resistance. Silicone-based systems excel in extreme temperature applications, and hybrid materials combine different polymers to achieve optimized performance profiles. Fillers like carbon black or silica reinforce the matrix, plasticizers adjust flexibility, and antioxidants prevent degradation—each component meticulously balanced to meet specific engineering requirements.

Installation methodology proves equally crucial to material performance. Proper surface preparation, primer application, and adherence to temperature thresholds during installation significantly impact long-term functionality. The substrate must be clean, sound, and properly profiled to achieve adequate bonding. Installation during inappropriate weather conditions—too hot, too cold, or damp—can compromise adhesion and lead to premature failure. The sequencing of joint installation relative to other construction activities requires careful planning to avoid damage during subsequent work phases.

Beyond material properties, the design of the joint system itself involves sophisticated engineering calculations. Movement capacity calculations must account not only for thermal expansion but also for creep, shrinkage, dynamic loads, and seismic activity where applicable. The joint width must accommodate the total expected movement while maintaining seal integrity throughout the range. Finite element analysis helps engineers visualize stress distribution and optimize joint placement and configuration. These calculations become particularly complex in structures with irregular shapes, mixed materials, or unusual thermal profiles.

The consequences of inadequate expansion joint systems manifest in various failure modes. Compression failure occurs when joint material undergoes excessive compression, leading to bulging or extrusion. Tensile failure happens when movement exceeds the material's elongation capacity, causing tearing. Adhesive failure separates the material from the substrate, while cohesive failure involves internal splitting of the material itself. These failures often create cascading effects—water intrusion leads to rebar corrosion, freeze-thaw damage, or deterioration of underlying substrates, multiplying repair costs exponentially.

Innovation continues to drive the field forward. Recent developments include smart joints with embedded sensors that monitor movement, stress, and deterioration in real-time. Self-healing materials containing microencapsulated polymers that repair minor damage automatically represent another frontier. Sustainable formulations using recycled materials or bio-based polymers align with growing environmental concerns. These advancements don't merely improve performance—they transform expansion joints from passive components into active contributors to structural health monitoring and longevity.

The economic implications of proper expansion joint design extend far beyond initial material costs. While high-performance systems command premium prices, they represent a small fraction of total project costs yet disproportionately influence long-term maintenance expenses. The concept of life-cycle costing demonstrates how investing in superior joint systems yields substantial returns through reduced maintenance, extended service life, and minimized operational disruptions. This economic perspective increasingly drives specification decisions, particularly in public infrastructure where long-term stewardship responsibilities outweigh short-term budget considerations.

Looking forward, the field faces new challenges and opportunities. Climate change introduces more extreme temperature variations and weather events, demanding enhanced performance specifications. The trend toward larger and more complex structures pushes the boundaries of existing technology. Integration with Building Information Modeling (BIM) allows for more precise planning and coordination of joint systems within overall designs. These developments suggest that expansion joint technology will continue evolving from a specialized niche into an increasingly sophisticated discipline central to structural engineering.

Ultimately, the science of compensating for concrete's thermal expansion represents a perfect marriage of materials science and practical engineering. It demonstrates how understanding fundamental physical principles leads to technological solutions that, while often invisible to end-users, form critical components of our built environment's safety and durability. As structures grow more ambitious and environmental conditions more demanding, the humble expansion joint will continue to play an outsized role in ensuring these marvels of engineering stand the test of time and temperature.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025