In the intricate world of pharmaceutical packaging, the stability of medicinal formulations remains a paramount concern, directly influencing both efficacy and patient safety. Among the various packaging methodologies, blister packaging utilizing aluminum foil has emerged as a cornerstone technology, particularly for its exceptional barrier properties against environmental aggressors such as moisture, oxygen, and light. This article delves into the critical relationship between aluminum foil blister packaging and the temporal management of drug stability, exploring how this packaging form not only protects but also defines the shelf-life and integrity of pharmaceutical products.

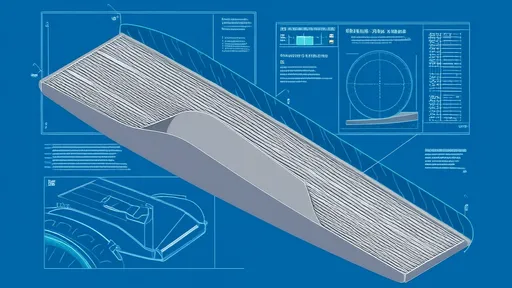

The primary function of any pharmaceutical packaging is to preserve the drug's chemical and physical properties from the point of manufacture until it reaches the end-user. Aluminum foil, often laminated with polymers like polyvinyl chloride (PVC) or polypropylene (PP), provides an almost impermeable shield. This barrier is crucial because many active pharmaceutical ingredients (APIs) are highly susceptible to degradation when exposed to atmospheric conditions. For instance, hydrolytic degradation can occur in the presence of moisture, leading to a reduction in potency, while oxidation can alter the chemical structure, sometimes producing harmful by-products. The hermetic seal achieved in well-manufactured blister packs significantly retards these processes, thereby extending the period during which the drug remains within its specified quality parameters.

Time management in this context refers to the scientifically determined period—the shelf-life—during which a drug product is expected to remain stable when stored under recommended conditions. The role of aluminum foil blister packaging is instrumental in guaranteeing this timeline. Stability studies, conducted as per ICH guidelines (Q1A(R2)), involve storing the packaged product under accelerated and long-term conditions to predict its behavior over time. Data from these studies demonstrate that aluminum foil blisters consistently outperform many alternative packaging materials in maintaining low moisture vapor transmission rates (MVTR) and oxygen transmission rates (OTR). This performance directly translates to a longer proven shelf-life for the medication, a critical factor for both patient access and commercial viability, especially for drugs distributed over vast geographical areas.

Beyond merely extending shelf-life, the design of the blister pack itself plays a role in time management from a patient adherence perspective. Unit-dose packaging, which blister packs exemplify, helps patients manage their medication schedule effectively. Each blister cavity, sealed with aluminum foil, represents a single dose, clearly marked often with days of the week or specific times. This not only minimizes the risk of missing a dose or double-dosing but also protects the remaining doses from exposure each time one is popped out. Therefore, the packaging actively contributes to the stability of the individual doses throughout the entire course of treatment, ensuring that the last dose is as potent and safe as the first.

The selection of the specific aluminum foil laminate is a nuanced decision that directly impacts the drug's stability timeline. Different drugs have different vulnerabilities. For a highly hygroscopic API, a foil laminate with an exceptionally low MVTR is non-negotiable. For a drug sensitive to photodegradation, an opaque aluminum foil provides complete light protection. Manufacturers must conduct comprehensive compatibility tests to ensure there are no interactions between the drug formulation and the packaging materials that could leach into the product or catalyze degradation over time. This tailored approach ensures that the time management strategy is optimized for each unique pharmaceutical product, safeguarding its stability from production to consumption.

In conclusion, aluminum foil blister packaging is far more than a simple container; it is an active, integral component in the strategic time management of pharmaceutical stability. Its superior barrier properties provide a robust defense against environmental factors, directly enabling the achievement of extended shelf-lives as validated through rigorous stability testing. Furthermore, its unit-dose format supports patient adherence, protecting the integrity of each individual dose throughout the therapy duration. As pharmaceutical science advances with more complex and sensitive biologics and APIs, the role of sophisticated, reliable packaging like aluminum foil blisters will only grow in importance, continuing to serve as a guardian of drug efficacy and patient health over time.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025